Contents

- Machine Vision Market Outlook

- Top 10 Machine Vision Technologies in 2025

- Averroes.ai – Visual Inspection & Virtual Metrology System

- Cognex – In-Sight L38 3D Vision System

- LandingAI – LandingLens Vision System (LVMs)

- Pleora Technologies – Real-Time Imaging Software

- OMRON Automation – Vision Software

- IVISYS – Logistics Automation Vision

- LabVIEW by National Instruments

- Optotune – Adaptive Lenses

- Basler AG – Smart Vision System

- Top 10 Machine Vision Companies (2025)

- What To Avoid When Choosing a Machine Vision System

- Applying Machine Vision in Business: Where Precision Meets Scale

- GEM Corporation: A Strategic Partner for Vision-Driven Systems

- Conclusion

- What is driving the global growth of the machine vision market?

- How are businesses using machine vision to improve operations?

- What challenges do businesses face when deploying machine vision systems?

- Why does expert implementation matter in machine vision projects?

- How does GEM Corporation support businesses in applying machine vision?

For businesses aiming to lead in smart manufacturing and AI-powered automation, adopting machine vision is now essential for a competitive edge in 2025. Modern vision systems are setting new benchmarks for speed, intelligence, and flexibility, driving applications from robotics guidance to real-time quality control. The challenge lies in selecting the right solution from a crowded field of emerging technologies and vendors.

Machine Vision Market Outlook

Source: https://www.grandviewresearch.com/industry-analysis/machine-vision-market

The global machine vision market is entering a new phase of acceleration, shaped by the convergence of manufacturing automation, AI integration, and real-time quality control demands. Valued at approximately USD 20.4 billion in 2024, the market is projected to reach USD 41.7 billion by 2030, reflecting a compound annual growth rate (CAGR) of 13.0% between 2025 and 2030.

Demand is being led by sectors where precision, speed, and scalability are non-negotiable, such as electronics, automotive, logistics, and pharmaceuticals. In these industries, machine vision systems support use cases like defect detection, barcode identification, and robotic guidance, often operating with accuracy rates above 99.5%.

- Segment Dynamics

- Hardware remains the largest revenue contributor, accounting for over 60% of market share in 2024. This includes industrial cameras, optics, and image processors, components that require high upfront investment but form the foundation of every MV solution.

- Software, while smaller in absolute size, is expanding faster. AI-based image analysis and deep learning algorithms are unlocking new use cases and driving double-digit growth.

- Smart Cameras and 3D Vision Systems are among the fastest-growing technologies, driven by the need for compact, integrated solutions and enhanced depth perception in tasks like bin picking and robotic alignment.

- Application Trends

- Quality Assurance & Inspection continues to dominate, as manufacturers seek zero-defect production standards.

- Identification applications – barcode scanning, pattern recognition, and object tracking, are seeing rapid adoption, particularly in supply chain and logistics environments.

- Regional Insight

- Asia-Pacific leads the global market, accounting for over 30% of total revenue in 2024, supported by manufacturing-intensive economies such as China, Japan, and South Korea.

- Growth Drivers

- The rollout of Industry 4.0 frameworks is pushing industrial players to adopt machine vision for real-time data capture and process control.

- AI integration is reshaping how vision systems are trained and deployed, enabling more adaptive, context-aware automation.

- Stricter regulatory expectations and rising end-user standards are reinforcing the role of machine vision as a core enabler of high-precision manufacturing.

As machine vision technologies evolve, their relevance is expanding into sectors like agriculture, healthcare, and smart retail, where visual intelligence offers new dimensions of automation and insight.

Top 10 Machine Vision Technologies in 2025

Averroes.ai – Visual Inspection & Virtual Metrology System

Averroes.ai combines AI-driven image analysis with virtual metrology to deliver high-precision inspection without relying on physical measurement tools.

Features and Benefits

- Combines AI-driven visual inspection with virtual metrology to simulate physical measurements.

- Reduces dependency on manual gauges, accelerating feedback loops in precision manufacturing.

- Designed for seamless integration with MES platforms, supporting inline quality control.

Drawbacks

- High upfront cost may limit accessibility for smaller manufacturers.

- Operator training is required to manage AI model updates and interpret output confidently.

Cognex – In-Sight L38 3D Vision System

Cognex’s In-Sight L38 offers 3D laser-based inspection with built-in deep learning, built for high-speed defect detection in complex manufacturing environments.

Features and Benefits

- Uses 3D laser displacement for capturing micro-defects and surface variation.

- Suitable for high-speed production lines in electronics, automotive, and medical devices.

- Deep learning tools onboard for real-time defect classification and adaptive inspections.

Drawbacks

- Performance depends on consistent lighting and controlled setups.

- Limited interoperability with third-party platforms outside the Cognex ecosystem.

LandingAI – LandingLens Vision System (LVMs)

LandingAI’s modular platform lets manufacturers train and scale custom vision models for multi-line inspection across diverse product categories.

Features and Benefits

- Centralised platform for training and deploying custom machine vision models at scale.

- Supports continuous learning through structured data pipelines and annotation tools.

- Built for manufacturers managing multiple SKUs across distributed lines.

Drawbacks

- Maturity varies across modules; some advanced features are still in development.

- Requires well-labeled datasets to maintain inspection accuracy across product variants.

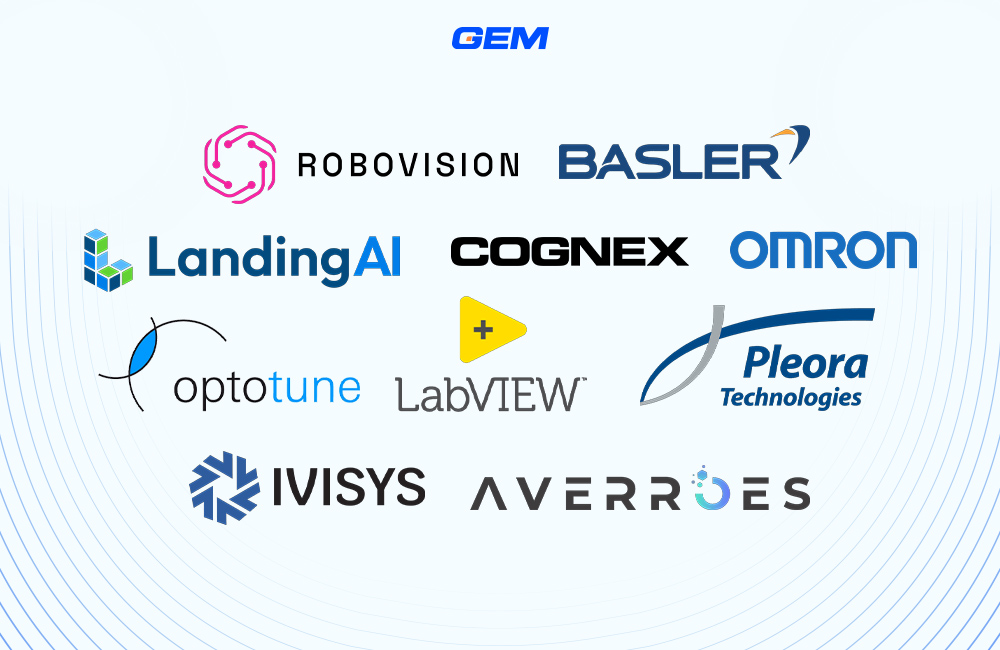

Robovision – Machine Vision Software

Robovision provides a no-code environment for rapid deployment of AI-based vision systems, adaptable across industries with minimal developer input.

Features and Benefits

- No-code interface allows operations teams to adapt inspection logic without engineering support.

- Cross-industry applicability, from agricultural grading to industrial quality control.

- Supports rapid iteration for evolving visual criteria in dynamic environments.

Drawbacks

- Generalist design may fall short for highly specialised or regulated workflows.

- Offline capability is limited compared to traditional PC-based systems.

Pleora Technologies – Real-Time Imaging Software

Pleora delivers low-latency imaging software for visual systems that require fast, frame-level decisions across automated inspection workflows.

Features and Benefits

- Enables low-latency image streaming and processing for time-sensitive inspection tasks.

- Compatible with a range of interface protocols, including GigE Vision and USB3.

- Often used in systems requiring frame-level decision-making, such as packaging or electronics testing.

Drawbacks

- System performance is closely tied to supported hardware.

- Customisation may be required for domain-specific workflows or analytics.

Are Inefficiencies Draining Your Resources? Let’s Fix That!

With GEM’s cutting-edge solutions, we’ll help you streamline workflows, optimize operations, and set your business up for sustainable success.

OMRON Automation – Vision Software

OMRON’s vision tools offer integrated inspection capabilities tailored for seamless use within its broader automation ecosystem.

Features and Benefits

- Integrates directly with OMRON PLCs and motion systems, simplifying setup and synchronisation.

- Offers pre-configured inspection tools for pattern matching, edge detection, and measurement.

- Designed to reduce engineering overhead in factory environments.

Drawbacks

- Primarily suited for users already invested in the OMRON automation stack.

- Limited flexibility for building or training models from scratch.

IVISYS – Logistics Automation Vision

IVISYS focuses on automating material handling through vision systems designed for label reading, object tracking, and bin picking in logistics.

Features and Benefits

- Tailored for logistics operations, including bin picking, carton identification, and conveyor tracking.

- Reduces manual handling through automated object detection and path planning.

- Plug-and-play configuration shortens deployment cycles in warehouse environments.

Drawbacks

- Scope is focused on material handling and logistics use cases.

- Not designed for high-precision manufacturing or scientific imaging.

LabVIEW by National Instruments

LabVIEW supports highly customisable machine vision development in research and prototyping environments, especially where sensor fusion is required.

Features and Benefits

- Offers a modular environment for image acquisition, processing, and sensor integration.

- Widely adopted in lab settings for prototyping machine vision workflows.

- Supports multi-sensor fusion and real-time control systems.

Drawbacks

- Requires programming experience to design and maintain complex vision applications.

- Licensing and ongoing support costs may be a barrier for smaller teams.

Optotune – Adaptive Lenses

Optotune’s tunable lenses improve focus speed and precision in dynamic settings by adjusting focal length electronically, without mechanical parts.

Features and Benefits

- Electrically tunable lenses dynamically adjust focal length without mechanical movement.

- Enables faster autofocus in robotic or handheld vision systems.

- Useful in environments with frequent object distance changes.

Drawbacks

- Needs careful calibration and voltage regulation for consistent performance.

- Must be integrated with compatible imaging software and controllers.

Basler AG – Smart Vision System

Basler’s edge-ready vision modules combine compact hardware with embedded AI, tailored for OEMs building scalable, real-time imaging products.

Features and Benefits

- Offers edge AI processing and compact form factors for embedded applications.

- High-res CMOS sensors deliver reliable imaging in low-light or fast-motion scenarios.

- Designed for OEMs needing scalable, space-efficient vision modules.

Drawbacks

- AI model customisation is limited without third-party development tools.

- Advanced capabilities often tied to premium licensing tiers.

Top 10 Machine Vision Companies (2025)

1. Intel

- Overview: Intel is a foundational provider in the machine vision space, offering a comprehensive suite of hardware and software tools. This includes their CPUs and VPUs (Vision Processing Units, such as Myriad), their RealSense depth cameras, and the OpenVINO toolkit for optimizing AI model deployment.

- Core Strength: Provides broad hardware-plus-software synergy and highly optimized tools for edge computing deployment.

- Best For: Original Equipment Manufacturers (OEMs), embedded systems, and developers building scalable, hardware-accelerated vision solutions.

2. Nvidia

- Overview: Nvidia is the dominant enabler for modern, AI-intensive machine vision due to its market-leading GPUs and dedicated Jetson edge computing modules. Its technology is essential for running complex deep learning models at high speed.

- Core Strength: Ubiquitous in AI training and inference, providing robust Software Development Kits (SDKs) like DeepStream and Isaac for real-time processing and robotics.

- Best For: Robotics, autonomous systems, and high-speed, real-time deep learning inference applications.

3. Qualcomm

- Overview: Qualcomm focuses on providing powerful, energy-efficient edge AI chips that integrate machine vision capabilities into mobile, automotive, and IoT devices. Their technology allows for sophisticated on-device processing without relying heavily on the cloud.

- Core Strength: Strong hardware-accelerated vision, known for being energy efficient and ideal for power-constrained or decentralized applications.

- Best For: Smart devices, autonomous driving platforms, and real-time analytics in consumer and mobile environments.

Make your digital transformation seamless and future-ready

Accelerate your business growth with zero-disruption modernization services. Maximize the value of your current infrastructure, streamline processes, and cut expenses.

4. LandingAI

- Overview: Founded by AI pioneer Andrew Ng, LandingAI specializes in a platform approach (LandingLens) designed to make machine vision accessible to enterprises, particularly when dealing with small datasets – a common challenge in manufacturing.

- Core Strength: Low-code model creation and training systems optimized for small data, enabling fast deployment and flexibility.

- Best For: Flexible manufacturing, electronics inspection, and precision Quality Assurance (QA) in environments where collecting millions of images is impractical.

5. SenseTime

- Overview: Based in Asia, SenseTime is a massive AI company known globally for its deep research in facial recognition and computer vision applications, particularly for large-scale urban infrastructure.

- Core Strength: Deep research expertise in AI vision, edge computing, and developing solutions for urban surveillance and infrastructure management.

- Best For: Surveillance, smart city infrastructure, and large-scale facial biometrics applications.

6. OMRON Group

- Overview: OMRON is a legacy leader in industrial automation that offers robust machine vision systems designed to integrate seamlessly with its broader ecosystem of programmable logic controllers (PLCs) and factory robots.

- Core Strength: Globally trusted brand with a wide device ecosystem, providing seamless factory integration for users already operating within the OMRON automation environment.

- Best For: Automotive, electronics, and medical device manufacturing that requires reliable, integrated industrial robotics and QA systems.

Read more: Automate Repetitive Tasks with RPA (Robotic Process Automation)

7. Verkada

- Overview: Verkada offers a modern, unified solution that combines security cameras with advanced computer vision and cloud-based software to deliver intelligent surveillance and security insights.

- Core Strength: Provides an intuitive, unified security platform with strong cloud software and an easy-to-use interface, focused on monitoring spaces.

- Best For: Enterprise building security, retail chains, and schools needing intelligent surveillance and monitoring rather than precision defect inspection.

8. Mech-Mind Robotics

- Overview: A Chinese technology company specializing in AI+3D machine vision solutions tailored for complex industrial robotics tasks, such as handling randomly placed objects.

- Core Strength: Specializes in providing strong ROI in automation through advanced 3D vision systems, which are essential for guiding robotic arms accurately.

- Best For: Bin picking, de-palletizing, and complex assembly automation in logistics and manufacturing environments.

Transform Your Business with the Power of Technology

Adopt AI, cloud solutions, and advanced analytics to reimagine your operations and stay ahead of the competition. Let’s future-proof your business together.

9. Orbital Insight

- Overview: This company focuses on a niche application: geospatial analytics. It utilizes satellite and aerial imagery combined with computer vision AI to monitor patterns like oil storage, urban expansion, and global logistics activity.

- Core Strength: Powerful processing of satellite data to generate high-level, strategic geographical insights for commercial and government use.

- Best For: Governments, financial services, and global logistics/supply chain companies requiring large-scale external monitoring.

10. OrCam

- Overview: OrCam develops highly compact, AI-powered wearable vision technology designed to assist visually impaired individuals by reading text, recognizing faces, and identifying products in real-time.

- Core Strength: Compact, personal, and highly accessible real-time assistive technology designed to enhance personal independence.

- Best For: Personal assistive technology for the blind and visually impaired, falling outside of traditional industrial or manufacturing machine vision.

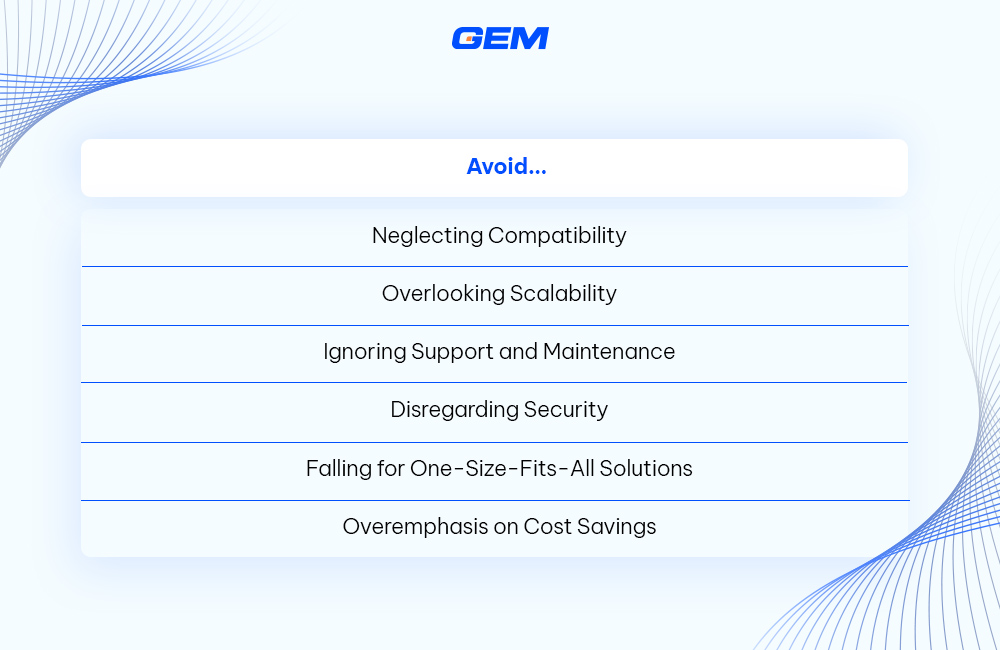

What To Avoid When Choosing a Machine Vision System

- Neglecting Compatibility: Choosing a system that doesn’t integrate well with your existing equipment or software can lead to costly downtime and complicated workarounds.

- Overlooking Scalability: A system that works for today might not support the demands of future production volumes or use cases. Plan for growth.

- Ignoring Support and Maintenance: Even the best systems will encounter issues. Ensure your vendor provides timely support, updates, and documentation.

- Disregarding Security: With more vision systems connected to the cloud, neglecting cybersecurity can expose your operations to risk.

- Falling for One-Size-Fits-All Solutions: Not all machine vision problems are created equal. Avoid generic systems that don’t cater to your specific needs or industry nuances.

- Overemphasis on Cost Savings: Cutting corners to save on initial costs can result in higher total cost of ownership due to poor performance or frequent failures.

Facing all these potential pitfalls can leave teams frustrated, waste valuable time, and drain resources that could otherwise be focused on growth and innovation. Identifying inefficiencies early and addressing them effectively is key to smoother, more productive operations.

Bring your ideas to life faster than ever before

Our agile solutions streamline workflows and cut time-to-market, helping you launch innovations quickly and confidently.

Applying Machine Vision in Business: Where Precision Meets Scale

Machine vision is becoming a core component of modern operational systems, used not only to detect defects or identify objects, but to drive decision-making across manufacturing, logistics, and retail. As businesses seek to automate inspection, improve traceability, and respond faster to quality issues, vision systems are increasingly deployed at the edge of production and supply chains.

Common applications include:

- Inline quality checks that flag anomalies in real time

- Barcode and label recognition for high-speed sorting

- Vision-guided robotics for assembly or pick-and-place tasks

- Inventory monitoring through object detection and counting

What separates effective deployments from stalled pilots often comes down to system design. Vision technology doesn’t operate in isolation, it depends on structured data input, integration with existing workflows, and the ability to adapt to production variability. Lighting, camera positioning, image quality, and model training all affect system performance.

That’s where technical expertise becomes decisive. Businesses often work with specialists to:

- Select the right mix of hardware and software for their environment

- Train and refine AI models based on real-world conditions

- Align vision outputs with MES, ERP, or warehouse systems

- Maintain inspection accuracy as product lines evolve

Without this foundation, even robust vision tools can underperform. For companies aiming to scale visual automation, success is rarely about the capabilities of the camera, it’s about how well the system fits the business it supports.

Read more: ERP solutions to streamline manufacturing processeson

GEM Corporation: A Strategic Partner for Vision-Driven Systems

GEM Corporation is a global IT service provider with a delivery hub in Vietnam, supporting clients across Japan, Australia, Asia-Pacific, Europe, and North America. Since 2014, we have helped enterprises and growing tech companies build high-performance systems through a combination of software engineering, emerging technology expertise, and operational clarity.

Our 400+ IT professionals deliver across a wide spectrum, from digital strategy and custom application development to cloud-native services and enterprise integration. We are certified to ISO/IEC 27001:2022, ISO 9001:2015, and CMMI Level 3 standards, and serve as an official partner of Databricks and ServiceNow.

In the field of machine vision, we offer applied expertise in:

- AI Computer Vision development for inspection, object detection, and visual automation

- Smart camera integration and real-time visual processing

- NLP & vision hybrid systems for document analysis and industrial monitoring

- Custom model training for vision-guided robotics and quality control

Conclusion

Machine vision is reshaping how businesses approach quality control, automation, and data-driven operations. Its growth is being driven by industry-wide efforts to modernise production systems, integrate AI, and respond faster to operational variability. From defect detection to logistics tracking, the technology’s value lies in its ability to deliver accuracy at scale, when embedded into the right system architecture. Success depends not only on the tools, but on the expertise behind their implementation.

Talk to GEM to explore machine vision solutions tailored to your business.

How are businesses using machine vision to improve operations?

Companies apply machine vision in quality inspection, defect detection, barcode scanning, and robotic guidance. The technology is often integrated with MES, ERP, and automation platforms to streamline decision-making and reduce manual intervention.

What challenges do businesses face when deploying machine vision systems?

Common challenges include managing image data quality, aligning vision systems with existing workflows, and maintaining model performance across diverse environments. Hardware calibration and lighting conditions also impact system reliability.

Why does expert implementation matter in machine vision projects?

Machine vision systems require more than just hardware and algorithms. Expertise is needed to design inspection logic, train AI models, and ensure integration with operational systems. Without the right technical guidance, even advanced tools may underperform or fail to scale.

How does GEM Corporation support businesses in applying machine vision?

GEM provides end-to-end services in AI computer vision, visual automation, and system integration. With experience across manufacturing, logistics, and healthcare, GEM helps clients build scalable, production-ready solutions tailored to their specific operational needs.