Contents

AI in industrial automation is moving from pilot projects to large-scale deployment, reshaping how manufacturers approach production, maintenance, and supply chain decisions. Nearly 93% of companies consider AI a key technology for driving productivity in industrial settings. As adoption grows, the focus is shifting to targeted use cases, ranging from predictive maintenance to autonomous process control, supported by infrastructure advances like edge computing and industrial IoT. This article outlines where AI is being applied across operations, the technologies driving adoption, and what businesses should consider as they scale their efforts.

What AI Brings to Industrial Operations

Industrial operations have always relied on precision and consistency. AI introduces a new dimension – adaptive decision-making based on real-time data and historical patterns. As systems become more connected, AI is reshaping how manufacturers manage variability, forecast disruptions, and coordinate across functions.

Data-Guided Decision-Making Across Functions

AI systems process large volumes of data generated across the factory floor – machine logs, sensor readings, maintenance records, and supply chain inputs. This data is transformed into actionable insights that support faster, more informed decisions in production scheduling, inventory management, and equipment servicing.

For example, AI models can identify subtle shifts in equipment performance that precede breakdowns or detect inefficiencies in energy usage across production lines. In logistics, AI helps forecast demand fluctuations and recommend inventory adjustments in real-time. These applications allow operators and planners to move with greater precision, guided by data instead of intuition.

Shifting From Reactive to Predictive Models

Traditional industrial systems often rely on fixed schedules and post-incident analysis. AI enables a shift toward predictive operations, where potential issues are identified and addressed before they disrupt output.

Predictive models use historical and real-time data to forecast equipment failures, quality deviations, and supply delays. This approach reduces downtime and unplanned interventions, while aligning maintenance and production plans more closely with actual conditions. In many organizations, this transition has also allowed for better resource allocation and lower operating risk.

Managing Operational Complexity at Scale

Modern industrial environments involve thousands of connected assets, distributed teams, and dynamic supply networks. AI helps manage this complexity by identifying patterns and interdependencies that may not be visible through conventional monitoring systems.

For instance, AI can correlate machine behavior with environmental conditions, operator input, and upstream supply variations. It can also recommend adjustments in process control based on real-time quality data or external disruptions. When deployed at scale, these capabilities support more resilient and adaptive operations, without requiring constant manual oversight.

Together, these shifts mark a move toward an operating model where decisions are made closer to the data and where systems adapt continuously to changing conditions.

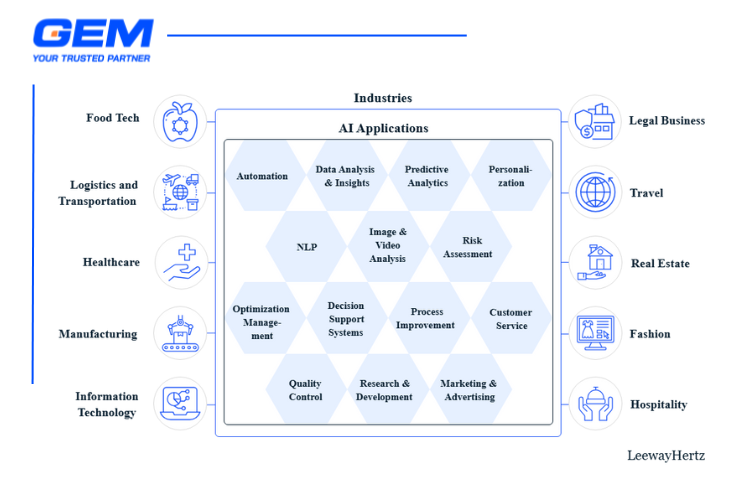

AI in Industrial Automation: Use Cases

The role of AI in industrial automation is defined by its ability to manage complexity, improve forecasting, and support real-time decision-making across core operational areas. The following categories represent the most active and impactful use cases being deployed in industrial settings today.

Predictive and Prescriptive Maintenance

Condition-Based Failure Forecasting

Sensor data from motors, pumps, and compressors is continuously analyzed to identify abnormal vibration patterns, thermal shifts, or acoustic anomalies. AI models detect early indicators of mechanical failure, allowing teams to act before breakdowns occur. This helps reduce unplanned downtime and extends the usable life of critical assets.

Prescriptive Maintenance Scheduling

AI systems not only predict when a failure might happen but also recommend the most effective maintenance action. The model evaluates cost, lead time for parts, and production schedules to suggest optimal intervention windows. This approach helps align technical priorities with operational constraints.

Twin-Driven Asset Lifecycle Optimization

Digital twins simulate equipment behavior under different operating conditions. When integrated with AI, these systems analyze historical and real-time data to assess wear patterns and performance degradation. Maintenance teams use these insights to prioritize repairs and defer non-critical replacements without increasing operational risk.

Explore: https://gem-corp.tech/manufacturing/ai-use-cases-success-stories

Quality Control and Defect Detection

Real-Time Defect Recognition in Visual Inspection

Computer vision systems inspect products on the production line to identify scratches, misalignments, or missing components. AI models compare live images with reference standards, flagging defective items before they move downstream. The process reduces rework, waste, and customer returns.

Anomaly Detection in Process Quality

Beyond surface-level defects, AI models monitor process variables like temperature, pressure, and flow rate to identify hidden quality risks. These systems learn from historical deviations and flag patterns that typically precede defects. Operators receive alerts early enough to adjust settings proactively.

Adaptive Quality Control in Variable Environments

In facilities producing multiple product configurations, quality thresholds can shift with each batch. AI systems adjust inspection parameters based on real-time production data, material inputs, and machine conditions. This supports consistent output across high-mix production lines.

Process Optimization and Control

Closed-Loop Process Tuning with Reinforcement Learning

AI agents continuously test and adjust process parameters, such as mix ratios and feed speed, to maintain optimal output. Over time, the system learns which settings provide the best performance under various conditions. This leads to more stable operations and reduces the need for manual fine-tuning.

Machine State Monitoring for Throughput Optimization

Edge AI devices track machine idle time, minor stoppages, and cycle durations across production cells. A real-time dashboard calculates performance losses and suggests adjustments in line balancing or operator assignments. This helps teams maintain throughput targets across shifts.

AI-Driven Batch Scheduling

AI scheduling engines assess constraints like machine availability, cleaning cycles, and labor shifts to create efficient production sequences. The system recalculates in real time if any resource becomes unavailable, supporting higher asset utilization and minimizing schedule overruns.

Supply Chain and Inventory Forecasting

Dynamic Demand Forecasting for Procurement Planning

AI models analyze historical sales, seasonal patterns, and external signals, such as weather or promotions, to forecast demand with higher accuracy. Procurement teams use these insights to plan orders and adjust safety stock levels, lowering both shortages and excess inventory.

Intelligent Inventory Tracking in Warehouses

Computer vision and IoT sensors monitor stock levels, picking accuracy, and space utilization. AI systems flag inconsistencies between recorded and actual inventory in real-time, minimizing audit discrepancies and supporting just-in-time restocking.

Real-Time Routing and Supply Risk Alerts

AI systems model logistics flows and identify risk factors like traffic delays, customs bottlenecks, or supplier disruptions. The system recommends alternate routes or suppliers based on current conditions. This helps mitigate delivery delays and maintain continuity in production.

Human-Machine Collaboration

Operator Guidance via AI Decision Support

AI systems assist frontline workers by providing step-by-step recommendations during setup, calibration, or troubleshooting tasks. The interface adapts based on machine state and previous operator actions. This reduces error rates and shortens training time for new staff.

Learning-Enabled Collaborative Robotics

Cobots equipped with AI learn from operator behavior and adjust their motion in real-time. For instance, if a human worker pauses or shifts position, the robot adapts its path to maintain safety and continuity. These systems are deployed in assembly, packaging, and inspection tasks.

Voice-activated Workflows for Technicians

AI-powered voice interfaces allow technicians to access manuals, log issues, or request parts using natural language commands. This supports hands-free operation in environments where mobility and speed matter. The system also logs interactions for future analysis.

Safety, Compliance, and Risk Mitigation

Visual Safety Compliance Monitoring

AI systems analyze live footage from shop floor cameras to verify whether workers are wearing the required PPE. Non-compliance events trigger real-time alerts to supervisors. This supports proactive enforcement without increasing inspection overhead.

Pattern-Based Risk Detection in Operations

Operational data is monitored for patterns that typically precede safety incidents—such as pressure spikes, unauthorized access, or abnormal machine states. AI models flag these early and recommend targeted intervention. This lowers incident rates and response time.

Wearable Monitoring for Exposure and Fatigue

AI-enabled wearables track vibration exposure, posture, and movement to detect signs of fatigue or unsafe conditions. When thresholds are exceeded, alerts are sent to both the worker and the control team. These systems reduce long-term health risks and support a safer work environment.

These use cases reflect how AI is being embedded into core industrial systems, not as standalone tools, but as operational layers that support visibility, consistency, and responsiveness across functions. As adoption expands, these categories will continue to shape how industrial organizations approach performance, safety, and scale.

Explore more: Top 15 Software Outsourcing Company In Vietnam (Updated 2025)

Technology Enablers and Infrastructure Requirements for AI in Industrial Automation

The deployment of AI in industrial automation demands an integrated technology stack that supports data flow, model reliability, and system interoperability.

Edge Computing, 5G, and Industrial IoT

- Edge Computing

Industrial operations generate vast volumes of time-sensitive data from machines, sensors, and control systems. Processing this data centrally introduces latency and bandwidth issues, particularly for real-time applications such as defect detection or autonomous control. Edge computing addresses this by bringing computation closer to the source, on machines, gateways, or local servers, so that AI models can run with low latency and respond immediately to changing conditions.

- Industrial IoT

The industrial IoT (IIoT) ecosystem provides the connectivity and data foundation for AI systems. Sensors embedded in production lines, fleet vehicles, and warehouses collect granular data on temperature, vibration, torque, and material flow. These signals serve as inputs for AI models that detect anomalies, predict failures, or optimize resource use.

- 5G

5G connectivity further strengthens this framework by offering high-speed, low-latency communication between devices and systems. In large-scale facilities or distributed networks, 5G enables real-time data transmission between edge devices, cloud platforms, and control centers, supporting coordinated AI decisions across the operation.

Scalable Data Pipelines, Model Governance, and MLOps

- Data Pipelines

AI solutions in industrial settings must operate reliably under varying conditions, across shifts, geographies, and asset types. This requires robust data pipelines that can ingest, process, and serve data at scale. Raw signals need to be filtered, contextualized, and structured before they can feed AI workloads. Many organizations adopt hybrid architectures that combine cloud- and edge-based processing to balance performance and compute efficiency.

- Model Governance

Once deployed, AI models must be monitored, retrained, and versioned through structured workflows. Model governance ensures that outputs remain consistent, explainable, and compliant with safety or regulatory requirements. This is particularly relevant in sectors where AI is applied to safety-critical decisions, such as predictive maintenance or quality inspection.

- MLOps

MLOps (Machine Learning Operations) provides the operational framework for managing the AI lifecycle, from training and validation to deployment and monitoring. In production environments, MLOps helps teams respond to data drift, performance degradation, or changing operating conditions. It also supports collaboration between data scientists, engineers, and domain specialists by standardizing workflows and deployment pipelines.

Integration with Legacy Industrial Control Systems (ICS)

A major consideration in industrial AI adoption is the coexistence of new systems with legacy infrastructure. Many factories run on programmable logic controllers (PLCs), SCADA systems, and proprietary protocols developed decades ago. These systems were not designed for AI integration and often present data accessibility or compatibility challenges.

Rather than replacing legacy equipment, organizations are implementing middleware layers and protocol converters that translate ICS signals into usable data streams for AI models. Lightweight agents or edge modules “listen” to machines and relay information to AI platforms without disrupting control logic.

This approach allows AI to operate in parallel with existing systems—augmenting decision-making without compromising safety or stability. In some cases, AI insights are delivered to operators via dashboards or alerts, while final control actions remain manual. In more mature settings, AI outputs are fed back into control loops through configurable APIs or supervisory systems.

AI in Industrial Automation: What is Blocking Adaptation?

Despite growing interest and clear value potential, the path to implementing AI in industrial automation remains uneven. Beyond technical readiness, organizations face structural, operational, and cultural challenges that can delay or limit impact.

Data Availability, Quality, and Ownership

Industrial AI systems depend on large volumes of structured and unstructured data. Yet in many facilities, data is fragmented across machines, spreadsheets, legacy systems, and handwritten logs. Inconsistent formats, lack of contextual metadata, and limited labeling make it difficult to train models that perform reliably in production.

Ownership is a significant concern, especially in multi-vendor environments or joint ventures. It’s often unclear who has control over the data – OEMs (Original Equipment Manufacturers), operators, or third-party integrators. This lack of clarity can make organizations reluctant to centralize their datasets or utilize cloud-based tools. A well-structured data strategy that emphasizes consolidation, labeling, and access controls is frequently the essential foundation needed for scalable AI deployment.

Talent and Organizational Readiness for AI-Driven Operations

Most industrial organizations were not designed around data science workflows. While many have strong engineering teams, they often lack in-house AI talent with experience in machine learning, MLOps, or real-time analytics. Recruiting and retaining this talent remains competitive, and upskilling internal teams takes time and structured investment.

Beyond technical skills, operational readiness is a barrier. AI adoption requires changes in decision-making processes, maintenance planning, and production oversight. When teams view AI as a top-down technology or a threat to existing roles, adoption slows. Engagement improves when operators, engineers, and supervisors are involved early, especially in identifying pain points that AI can address.

Interoperability and Vendor Lock-In Risks

Industrial environments often include multiple generations of machines, software platforms, and network protocols. AI solutions must interface with this complex ecosystem, yet many tools are built with limited compatibility. Proprietary data formats, closed APIs, and hardware-specific requirements can create friction during integration.

This fragmentation also increases vendor lock-in risk. Organizations that invest in AI tools tied to specific platforms may face high switching costs or limited flexibility down the line. To manage this, some manufacturers are prioritizing modular solutions with open standards and interoperability as core selection criteria.

Security and Compliance Concerns in OT Environments

Operational technology (OT) systems are designed for stability and uptime, not rapid updates or external integrations. Introducing AI into OT environments, especially when cloud connectivity is involved, raising concerns around cybersecurity, data leakage, and regulatory compliance.

AI models that access or process sensitive production data must be deployed with strict access controls and audit trails. In regulated industries, such as pharmaceuticals or food processing, the explainability of AI decisions is also a compliance requirement. Many organizations are still building the governance frameworks needed to deploy AI safely in these contexts.

While the technical foundation for AI in industrial automation continues to strengthen, adaptation is shaped by how well businesses address these structural challenges. For many, progress depends less on model sophistication and more on data readiness, workforce alignment, and integration strategy.

GEM Corporation is a leading mid-sized IT partner specializing in technology solution development, offshore/onshore professional services, and practical Data & AI enablement.

Founded in 2014, GEM has delivered secure, high-impact technologies for Fortune 500 enterprises and empowered successful startups across Japan, Asia-Pacific, and Europe.

With 400+ IT professionals, we operate on a core philosophy of speed, quality, and reliability -where quality is our key differentiator in a market that often compromises it.

Our commitment to excellence is backed by globally recognized standards and partnerships:

- ISO/IEC 27001:2022, ISO 9001:2015, and CMMI Level 3 certified for software development

- ISTQB Gold Partner for Quality Governance

- Official Consulting Partner of Databricks and ServiceNow

For more information:

- GEM Global: GEM Corporation – Professional IT Services And Consulting

- GEM Korea: GEM – 베트남의 전문 IT 서비스 제공업체

- GEM Japan: GEM -ベトナムの専門ITサービスプロバイダ

Explore:

- AI Adoption in Businesses – Complete Guide with 6 Steps

- Top 35+ NLP Projects

- Top 5 Phase of NLP

Key Takeaways

AI in industrial automation is no longer limited to isolated pilots. It is being integrated into core functions, maintenance, quality, scheduling, and safety, across production environments. As the shift from experimentation to operational scale continues, success depends on data readiness, infrastructure alignment, and cross-functional adoption. The organizations moving forward are those embedding AI directly into their systems and workflows, not treating it as an add-on. This approach defines the foundation for resilient, responsive, and intelligent industrial operations.

To explore how AI can solve your most pressing operational challenges

Connect with GEM’s team of domain and technology experts!

Don’t hesitate to contact us and start a conversation about building AI solutions tailored to your business.